FKM(Fluoroelastomer)

FKM (Fluoroelastomer)

FKM is copolymer of vinylidene fluoride and hexafluoropropene. The content of fluorine is 66% byweight. It can be molded, extruded or injected into rubber products, such as O-rings, gaskets, seals and diaphragms as well as hoses etc.

Items | 26202 | 26302 | 26404 | 26504 | 26704 | 26902 | 26120 | 26140 |

Mooney viscosity (ML(1+10)1210C) | 20-29 | 30-39 | 40-49 | 50-59 | 65-85 | 90-99 | 110-129 | 130-149 |

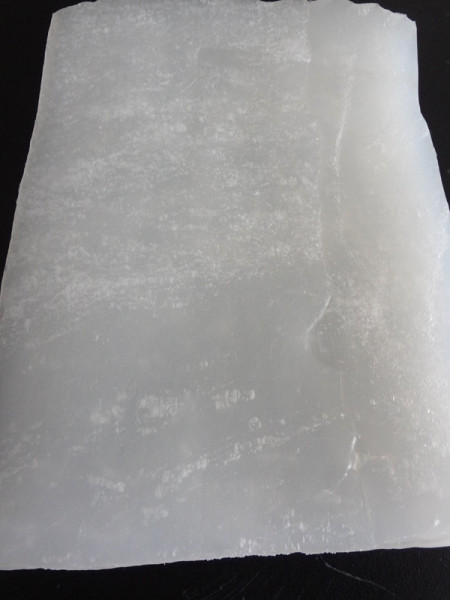

Appearance | White or light-yellow flake | |||||||

Fluorine content(%) | 66 | |||||||

Density (g/cm3) 23 0C | 1.82+0.02 | |||||||

Tensile strength after press cure (MPa) 1770C,10min≥ | 8 | 8 | 9 | 9 | 9 | 9 | 10 | 10 |

Tensile strength after post cure(Mpa) 2300C,24H≥ | 10 | 10 | 11 | 11 | 12 | 12 | 13 | 13 |

Elongation at break after press cure (%)1770C,10min≥ | 200 | 200 | 200 | 200 | 200 | 200 | 180 | 180 |

Elongation at break after post cure (%)2300C,24H≥ | 180 | 180 | 180 | 180 | 180 | 180 | 160 | 160 |

2000C 70H Compressibility 20% Compression set (%)≤ | 20 | 20 | 20 | 20 | 20 | 20 | 12 | 12 |

2. The basic formula:

FKM raw gum: 100g;

Bisphenol AF: 2g;

Vulcanization accelerator BPP: 0.5g;

MgO: 3g

N990 MT Carbon Black: 30g

Ca(OH)2: 6g;

3. Package, storage and transportation:

(2). Fluoroelastomer should bestored in clean, dry and cool warehouse. It can be transported as non-hazardous chemicals and should be far away from pollution sources, sunshine as well aswater during transportation.

(3). It is suggested that fluoroelastomer storing time limit should be one year after production. If exceeding one year, these products should be retested, they could be used continuously after being retested up to grade.

- Loading...

- *Title

- *Content

- Name:

- Eric Chan

- Tel:

0086-186-68076105

0086-571-87085102

- Email:

- sales@zjfotech.com

- WhatsApp:

- https://wa.me/8618668076105